Advanced Jaggery & Sugar Packaging Machines Driving African Mills Forward

Africa’s sugar business is on the rise, with sugar production estimated to amount to 14 million metric tons by 2030. Besides this, jaggery, a natural, unrefined sweetener, is on the increase in both export and domestic markets for its organic benefits. Despite this, African mills still grapple with widespread challenges such as inefficiencies in the process of sugar packaging, excessive wastage, and environmental obstacles such as dust and moisture.

In order to stay competitive, mills need to shift from archaic manual practices to modern sugar packaging machine solutions that provide hygiene, consistency, and scalability. Nichrome, a global leader in packaging machinery, introduces innovative technologies adapted for the African environment. These packaging machineries provide speed, strength, and cost-effectiveness.

Whether you own a mill in South Africa, Nigeria, or Kenya, investing in an automatic sugar packaging machine or sugar filling machine is the way forward to growth.

Africa’s Sugar & Jaggery Packaging Challenges

Sugar and jaggery might appear straightforward, but it is an intricate process to package them regularly and efficiently. Mills in Africa face several challenges, such as:

- Moisture sensitivity: Sugar and jaggery become lumpy when not properly sealed.

- Dusty environment: Impacts machines, lowers levels of hygiene, and decreases production.

- Shortage of labour: Manual packaging is slow, irregular, and expensive.

- Irregular packaging quality: Causes customer dissatisfaction and product rejection.

- Slow speed of packaging lines: Cannot keep pace with increasing market demand for sugar sachet packaging and bulk orders.

Unless the proper solutions are in place, these problems impact profitability and competitiveness in the market. Installing sugar packing machines and jaggery packing technologies is necessary.

Nichrome’s Advanced Packaging Solutions for Africa

Nichrome provides an extensive assortment of sugar packaging machines that are programmed to suit African conditions.

Features & Benefits:

- High-speed production to cater to the rising demand in Africa.

- Hygienic operation for safe, contamination-free products.

- Durability in dry and humid conditions.

- Easy integration with existing lines for smooth upgrades.

Machine Types & Technical Advantages

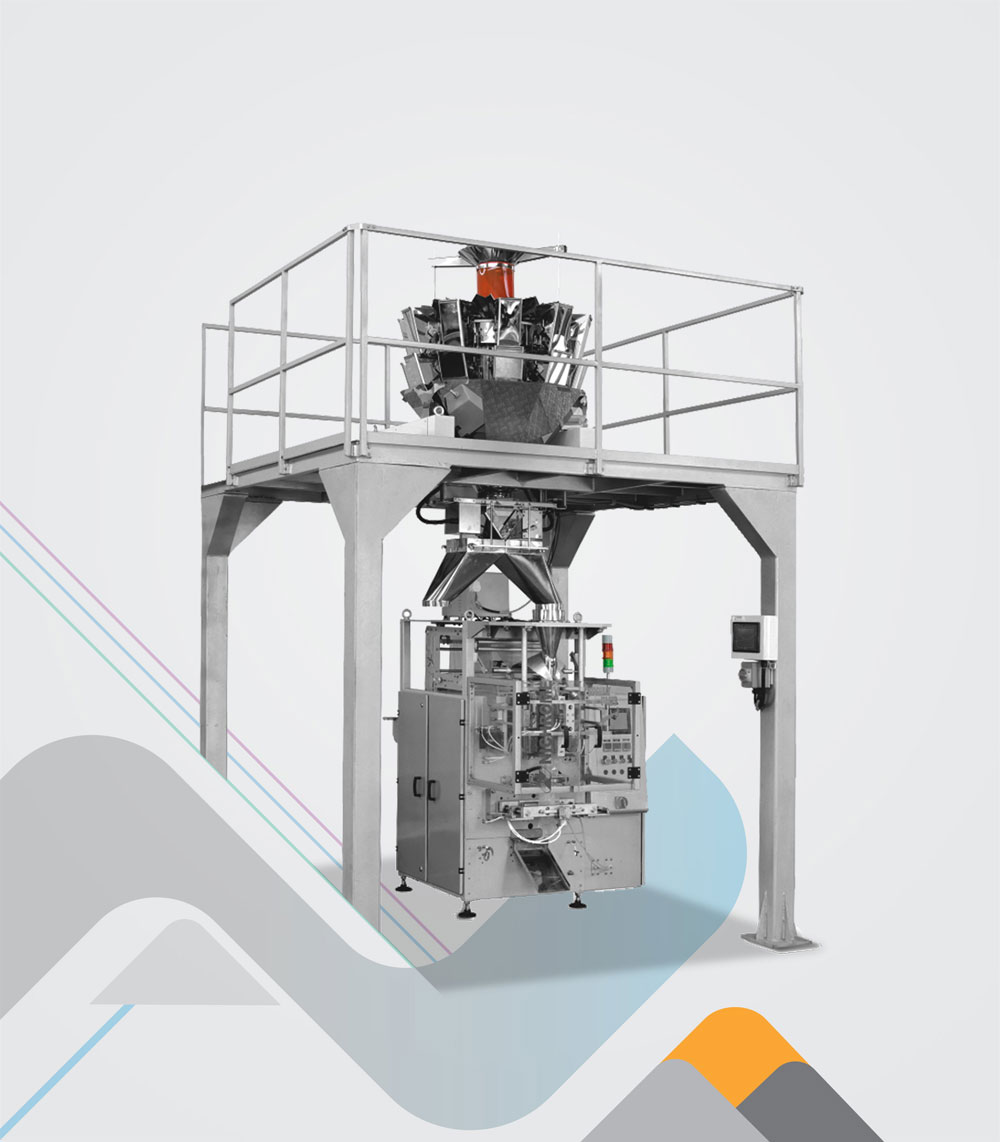

Excel 400 Plus VFFS machine

VFFS Sugar Packaging Machines

Nichrome’s Excel 400 Plus VFFS machine is ideal for big mills. It provides uniformity in powdered sugar packaging while ensuring cleanliness.

Pouch Packaging Machines for Sugar & Jaggery

The Sprint 250 Plus packs sachets fast and accurately, making it suitable for small to medium mills. It also provides flexibility in pack sizes, from single-serve sachet to mid-sized pouch.

Bulk Packaging Solutions

For wholesale sale, Nichrome’s bulk packaging division ensures that huge amounts of sugar or jaggery are packed into heavy-duty bags. This minimizes wastage and reduces labour dependency.

Jar Bottles and Carton Packaging

Jar bottles and carton packaging for sugar and jaggery increases shelf visibility. Carton packaging helps suppliers collect and deliver bulk orders while jar bottles are perfect for consumers who consume sugar and jaggery on a regular basis.

| Machine Model | Packaging Type | Speed (pouches/min) | Ideal For | Key Feature |

| Sprint 250 Plus | Sachet | 120 | Small-Medium Mills | Hygienic & Durable |

| Excel Plus | VFFS | 80 | Large Mills | High-Speed Output |

ROI & Competitive Advantage

Investing in Nichrome’s industrial food packaging machines is about reshaping the way African sugar and jaggery mills operate for long-term growth and sustainability.:

- Lower labour expenses: Manual packing requires a large workforce, which increases costs. By shifting to automation, mills not only save on labor expenses but also reduce dependency on seasonal or unskilled workers.

- Improved efficiency: A packaging machine ensures more packs per hour with fewer stoppages and errors. This allows mills to keep pace with rising demand.

- Better quality: Manual packing affects the uniformity of packaging. With Nichrome’s sachet filling machines, every pack is precise, clean, and visually appealing, boosting trust in the brand.

- Extended shelf life: Humidity increases sugar and jaggery from spoiling faster. Automated machines ensure airtight sealing and secure packaging, protecting the product from humidity ensuring the product stays fresh for longer.

- Stronger brand positioning: Consistently well-packed sugar and jaggery supermarkets and convenience stores enhances the mill’s reputation and competitiveness.

- Export readiness: Reliable packaging machinery ensures food safety and packaging standards on a global level, helping mills expand their reach.

In the competitive market, automatic packaging machines gain a competitive advantage by fulfilling demand earlier at reduced cost.

Market Trends & Future Outlook

The African food & packaging industry is fast changing. Some of the dominant trends influencing sugar and jaggery packaging are:

- Stick sachets: Convenient single-serve packaging formats for coffee shops, hotels, and airlines.

- Eco- friendly packaging: Biodegradable packaging pouches for environmentally friendly packaging.

- Automation: Increasing use of packaging machinery to manage increasing volumes.

- Digital printing: Promotes product & packaging appeal with bold branding.

With increasing consumer demands and export markets, those mills embracing advanced packaging machine industry technology will remain ahead.

Conclusion

Africa’s sugar and jaggery production is growing, but so are the hassles. From dust and humidity to inefficiencies in labour, manual processes are keeping mills behind. Nichrome’s sugar packaging machines, sachet filling machines, and bulk packing solutions provide the ideal upgrade by integrating speed, hygiene, and toughness.

By investing in the latest solutions from Nichrome, African mills can future-proof their businesses, capitalize on expanding retail and export markets, and improve their brand reputation. With efficiency aside, these machines also guarantee adherence to international food safety standards, facilitating wider markets and profitability.

FAQs

Q1. What is the best sugar packaging machine for African mills?

For small to medium mills, the Sprint 250 Plus sugar packing machine offers speed and durability. For larger mills, the Excel Plus VFFS machine delivers high-speed performance.

Q2. How can jaggery packaging machines reduce wastage?

Nichrome’s jaggery packing machines ensure airtight sealing, preventing spoilage and clumping due to moisture. This reduces wastage and improves product shelf life.

Q3. What speed can Nichrome sugar sachet packaging machines achieve?

Machines like the Sprint 250 Plus can deliver up to 120 sachets per minute, making them ideal for retail sugar packaging.

Q4. Which packaging machine is ideal for bulk sugar vs sachets?

Bulk sugar is best packed using Nichrome’s bulk powder packing machines (20–50 bags per minute), while sachets are better suited to sachet filling machines like the Sprint 250 Plus and Wings 200.